STRAIGHT SECTIONS

| Item No | rung spacing(RS) | width(w) |

|---|---|---|

|

EHL-150-1 EHL-150-2 EHL-150-3 |

150 230 300 |

150 |

|

EHL-230-1 EHL-230-2 EHL-230-3 |

150 230 300 |

230 |

|

EHL-300-1 EHL-300-2 EHL-300-3 |

150 230 300 |

300 |

|

EHL-450-1 EHL-450-2 EHL-450-3 |

150 230 300 |

450 |

|

EHL-150-1 EHL-150-2 EHL-150-3 |

600 600 600 |

600 |

|

EHL-750-1 EHL-750-2 EHL-750-3 |

150 230 300 |

750 |

|

EHL-900-1 EHL-900-2 EHL-900-3 |

150 230 300 |

900 |

| Item No | rung spacing(RS) | width(w) |

|---|---|---|

|

ELZ-150-1 ELZ-150-2 ELZ-150-3 ELZ-150-4 |

150 230 300 450 |

150 |

|

ELZ-230-1 ELZ-230-2 ELZ-230-3 ELZ-230-4 |

150 230 300 450 |

230 |

|

ELZ-300-1 ELZ-300-2 ELZ-300-3 ELZ-300-4 |

150 230 300 450 |

300 |

|

ELZ-450-1 ELZ-450-2 ELZ-450-3 ELZ-450-4 |

150 230 300 450 |

450 |

|

ELZ-600-1 ELZ-600-2 ELZ-600-3 ELZ-600-4 |

150 230 300 450 |

600 |

|

ELZ-750-1 ELZ-750-2 ELZ-750-3 ELZ-750-4 |

150 230 300 450 |

750 |

|

ELZ-900-1 ELZ-900-2 ELZ-900-3 ELZ-900-4 |

150 230 300 450 |

900 |

| Item No | rung spacing(RS) | width(w) |

|---|---|---|

|

ELL-150-1 ELL-150-2 ELL-150-3 |

150 230 300 |

150 |

|

ELL-230-1 ELL-230-2 ELL-230-3 |

150 230 300 |

230 |

|

ELL-300-1 ELL-300-2 ELL-300-3 |

150 230 300 |

300 |

|

ELL-450-1 ELL-450-2 ELL-450-3 |

150 230 300 |

450 |

|

ELL-150-1 ELL-150-2 ELL-150-3 |

600 600 600 |

600 |

|

ELL-750-1 ELL-750-2 ELL-750-3 |

150 230 300 |

750 |

|

ELL-900-1 ELL-900-2 ELL-900-3 |

150 230 300 |

900 |

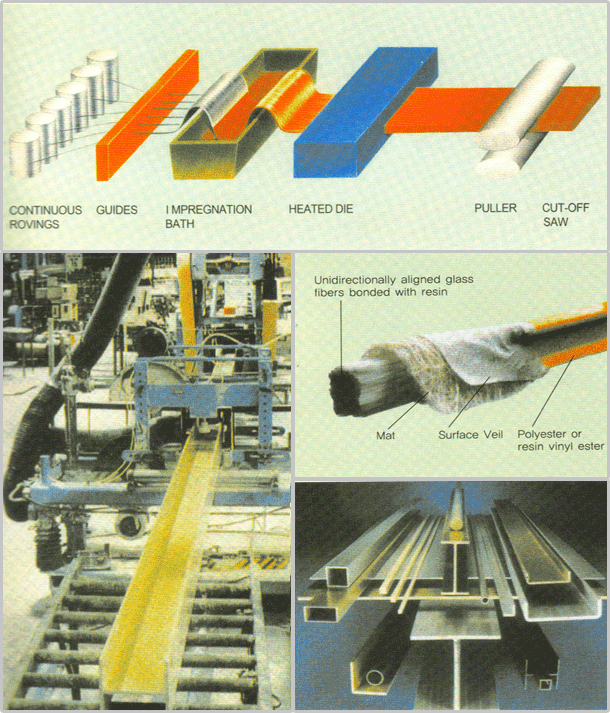

DONG SUNG fiberglass cable and instrumentation tray systems are designed and engineered to provide maximum protection when used in highly corrosive environments. DONG SUNG tray system components are manufactured from a combination of glass rovings and continuous strand glass mat for maximum strength and a nexus veil which acts as a containment mechanism for the glass and improves resin distribution, enhancing corrosion resistance. A chemical additive, introduced to the resin system, provides ultra-violet light protection.

DONG SUNG tray systems are manufactured from high quality polyester resin (color-gray) or vinyl ester (color-beige). Each resin is designed to provide maximum corrosion resistance to specific corrosive environments.

SUGGESTED SPECIFICATIONS

DONG SUNG CABLETRAY-EHL-ELZ-ELL

1.0 SCOPE

This specification covers the requirements for a cable tray system to support power, control and is instrumentation cables.

2.0 STANDARDS

2.1 The NEMA Standard EG-1 1984 covers continuous, complete, fiberglass systems of ladder, ventilated or solid bottom cable tray systems. Applicable sections in the standard shall cover the Dong Sung Fiberglass Cable Tray System.

3.0 MATERIAL

3.1 All cable tray, fittings and accessories shall be fabricated from fiberglass and shall be corrosion resistant and fire retardant.

3.2 The compositive material shall be Dong Sung Series FR polyester resin, or equal, combined with fiberglass reinforcement utilizing longitudinal glass roving and continuous stand mat.

3.3 The composite material shall have an ultraviolet light inhibiting chemical additive.

3.4 The side rails and rungs shall have a nexus veil to provide additional chemical resistance.

4.0 CABLE TRAY

4.1 The cable tray shall be ladder type with 230mm 300mm 450mm center rung spacing.

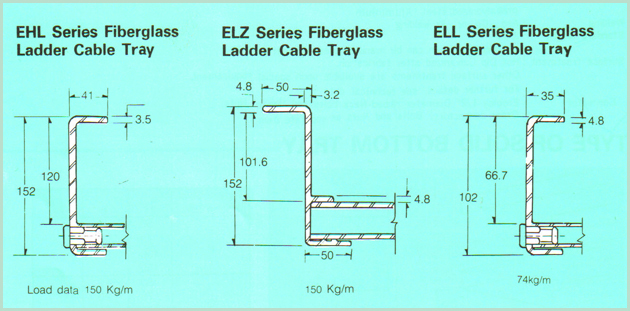

4.2 EHL, ELL

The rungs should be assembled through the use of a locking pin made of fiberglass impregnated polyester.

OR

ELZ

The tray shall be assembled through the use of a rivet and an adhesive to assure both a mechanical and chemical lock.

4.3 EHL, ELL

The locking pin, which provides both a mechanical and chemical lock between the side rail and rung, shall be inserted under pressure with a high strength, chemical resistant adhesive.

4.4 EHL

The side rails shall be nominal 152mm deep channel with approximately 127mm loading depth. The flanges of channel sections shall turn in.

OR

ELL

The side rails shall be nominal 100mm deep channel with approximately 75mm loading depth. The flanges of channel sections shall turn in.

OR

ELZ

The side rails shall be nominal 152mm deep "z" channel with approximately 100mm loading depth.

4.5 The tray shall be furnished in 2.4 Meter lengths and the width shall be shown on the drawings or indicated on the bill of materials.

5.0 FITTING

5.1 The manufacturer shall provide all required tray fittings. The side rails and rungs for tray fittings shall be the same materials and construction as the straight sections.

Channel radius of the fittings shall be have 300mm 600mm, or 900mm radius as requested.

5.2 All tray fittings shall have 230mm rung spacing.

6.0 CONNECTOR PLATES

6.1 Connector plates shall be design with sufficient strength so that they may be installed between 6 and 7 of the span from the support without derating the load carrying capacity of the tray or channel.

6.2 Adjustable expansion and adaptor type connections shall be available to make varying changes in size and direction and to allow for thermal expansion and/or contraction.

6.3 All connector plates for straight sections and fittings shall be of the same glass content and resin system as the tray.